Medical Device Manufacturing & Assembly Services

From the initial concept to delivery of your finished products, DUKE Empirical partners with you every step of the way. Our engineering team can guide you through our design control process, or we can support your internal product development process.

Let DUKE Empirical’s vast experience accelerate your product launch for your application-specific technology. Our mission is to provide manufactured products and services that consistently meet or exceed all defined requirements.

Proven Processes for Medical Device Manufacturing

We use a wide range of validated production processes and equipment. Our dedicated catheter manufacturing assembly processes take place within ISO Class VIII certified controlled environment rooms. All medical manufacturing, assembly, and related services are performed in-house to ensure quality and consistency.

When requested, our process begins with an understanding of your requirements and intended use as they are known at the time. From there we will create multiple design options, develop functional sample prototypes, test and compile data reports, and confirm that design outputs meet all requirements.

Upon prototype design freeze, we will finalize the product specification, qualify and validate manufacturing processes for your custom medical products and components and certify conformance to dimensional and functional requirements. To help expedite the process, DUKE can also assist with the transfer of your existing medical product manufacturing to our state-of-the-art 61,000 square foot facility.

Medical Manufacturing and Assembly Services

- Design for Manufacturing

- Pilot Production

- Commercial Manufacturing

- Quality

- Automation Solutions

- Assembly & Kitting

- Packaging

- Supply Chain Management

- Sterilization

- Regulatory Support

- Logistics

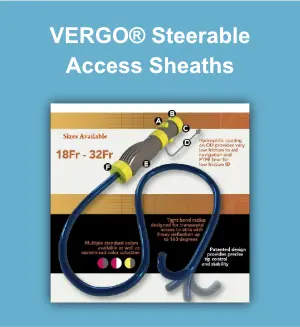

Catheter Manufacturing and Assembly Expertise

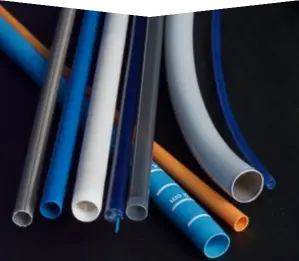

At DUKE Empirical, we’re more than just medical device developers—we are also medical material experts! We have extensive process expertise working with medical-grade polymers, biocompatible metals, and coatings for medical applications.

We have developed and marketed a proprietary line of polymers and resins that have been tested to meet USP Class VI biocompatibility requirements and are engineered to provide unique advantages for medical products.

These materials offer improved lubricity and higher performance for catheter and advanced medical technology products where strength, profile, flexibility, kink resistance, control, and deliverability are essential requirements.

Why Choose DUKE Empirical for Your OEM Contract Medical Devices Manufacturing?

At DUKE Empirical, we specialize in providing catheter manufacturing solutions for all of your application challenges. When you work with us over other catheter manufacturing companies, in addition to our superior materials, you will receive:

- Fastest Industrial Lead Time

- Dedicated Engineering & Development Resources

- Superior Customer Service

- Production within ISO Class VIII CER & ISO 13485:2016 Certified Quality & Management Systems

- Production within ISO 13485:2016 Regulations

Contact us to learn more about DUKE’s proprietary PebaSlix™, PolySlix™, NyloSlix™, and FluoroSlix™ materials. We offer the industry’s largest off-the-shelf inventory of tubing and related products, with immediate availability.

Quality System for Medical Product Manufacturing Assembly

Our quality system can facilitate the transfer of early-stage products into controlled manufacturing for pre-clinical product evaluation, physician preference testing, and clinical trials. We can transfer your designs from early-stage to commercial manufacturing, either as a component of a device that will undergo additional assemble at your facility or as a complete product that is packaged, labeled, sterilized and ready for distribution.

DUKE Empirical utilizes ISO Class 8 cleanrooms to extrude, manufacture, and assemble our medical tubing, catheter components, and finished goods. Our controlled environment rooms are monitored for particulate to the ISO 14644 standards. In addition to meeting the ISO standard for particulate, the rooms are monitored for microbiology, making them suitable for medical device manufacturing.

Specialists in Medical Design for Manufacturing and Assembly

DUKE Empirical specializes in the development of new products according to customer needs. We are the industry’s fastest product development company, thanks to our broad in-house capabilities, all of which are centered around the development and manufacturing of catheter and medical tubing products.

Our experience and expertise will help you take your new products through development and market launch in the shortest time possible.