Custom Catheter Designs for the Medical Market

Custom catheter devices provide design innovation for new and advanced medical procedures. DUKE Empirical produces custom catheters that span a wide range of clinical market segments and applications.

DUKE offers custom design and manufacturing options including but not limited to the following types of catheters:

DUKE Empirical Inc. is a leader in medical device tubing and catheter component manufacturing. We provide precision custom extrusions and deliver innovative proprietary materials development for a broad range of custom catheter applications. Our knowledgeable engineers understand that time is crucial when implementing a new product line, that is why DUKE Empirical offers the shortest lead times in the industry. We will manufacture, test, and develop a material solution that is 100% tailored to your project’s requirements.

Contact us for more information regarding our unique approach to your custom catheter application requirements, or call us at 831-420-1104 and we will gladly discuss your project’s specific needs. DUKE Empirical is your trusted source for custom medical device tubing and catheter-based medical devices.

We offer a range of innovative catheter products to assist in the fields of:

- Cardiovascular

- Structural Heart

- Neurovascular devices

- Drug Delivery Devices

- Orthopedic devices

- Gastrointestinal devices

- Oncology devices

- Reproductive health devices

Custom Catheter Application Options

At DUKE Empirical, our mission is to deliver valuable customer solutions for your explicit custom catheter application needs. We accomplish this through custom design, development, and manufacturing processes that meet your exact project requirements.

Custom Catheter Application Development & Manufacturing Processes

DUKE’s vertically integrated development and catheter manufacturing capabilities allow us to deliver highly engineered, innovative, and customized product solutions in the shortest time possible. Utilizing our five-step development and manufacturing approach, we can quickly develop a custom catheter that meets regulatory requirements for worldwide market launch.

DUKE Empirical utilizes ISO Class 8 cleanrooms to extrude, manufacture, and assemble our medical tubing, catheter components, and finished goods. Our controlled environment rooms are monitored for particulate to the ISO 14644 standards. In addition to meeting the ISO standard for particulate, the rooms are monitored for microbiology, making them suitable for medical device manufacturing. In addition to that, all production is within ISO-13485:2016 regulations.

Catheter Design

![Custom Catheter Development and Design]()

If you are not sure of the exact design approach, including material options, that your project requires, that’s ok. Our expert catheter design strategists and engineers will assist you in creating a catheter design that meets your design input requirements or in the absence of such requirements, as is typical for early concept stage feasibility studies, where product features are explored. We also assist with the development of design inputs based on plans for product marketing.

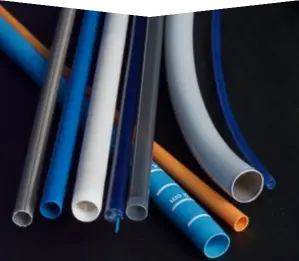

Medical Tubing Extrusions

Through our direct in-house manufacturing processes, DUKE will extrude your catheter materials within our facility. This allows us to control the precision of the components that are essential for the success of the final product, where changes can be made to obtain optimal results in the shortest lead times. Our premier extrusion services are branded as DUKE Extrusion and are a source for the critical components needed for their product development. By having this capability in-house lead times for products are shortened from weeks to days.

Catheter Wire Forming

We will also work closely with you to develop the catheter wire forming that is optimized for the desired device performance. Our custom, in-house wire forming capabilities allow for a wide range of custom options.

Secondary Operations

If your catheter requires even more enhanced customization (tip or lure), DUKE also provides advanced secondary operations to create a fully customized catheter.

Testing & Fulfillment

To confirm product quality and specification parameters are met, we will test and validate your catheter to applicable ISO standards in-house. The testing and validation process ensures that your catheter is designed, developed, and manufactured in compliance with all regulatory requirements.

In-House Medical Device Technologies for Your Custom Catheter Application Needs

At DUKE, our in-house medical device technologies allow us to completely control the quality of the design and manufacturing process. Our trusted supply partners require qualification through our Quality Management System to be on our Approved Supplier List. This qualification ensures your products will be built on time, with the necessary controls to ensure compliance with all regulations, and provides us with a controlled supply of the raw materials that are necessary for reliably developing and manufacturing high-quality catheters throughout the product life cycle.

In addition, we will provide continuous support and consultation throughout the catheter manufacturing and testing phases, delivering a catheter device that has been optimized to meet your goals and timelines for the product.

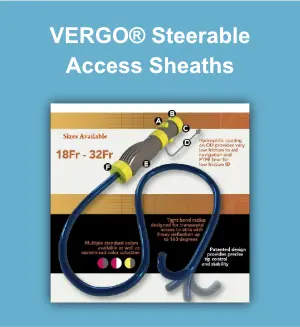

Discover DUKE's Latest Medical Component Product

Check out our VERGO® Steerable Access Sheaths. It comes in off-the-shelf sizes between 18Fr and 32Fr.